BABA ELECTROPLATERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to BABA ELECTROPLATERS

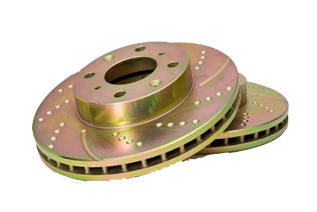

Zinc Nickel Electroplating

Zinc nickel plating has the ability to offer outstanding corrosion protection, especially when subjected to high temperatures. It is used extensively in automotive under body applications where its temperature and corrosion resistance are vital.the preferred alloy composition of zinc nickel plate is 12 – 15% nickel, with the remainder being zinc. This alloy gives exceptional sacrificial corrosion resistance and can be readily passivated. To achieve this alloy, zinc nickel is usually plated from an alkaline electrolyte

Features & Advantages

Corrosion protection

Typical rack plated component with colour passivate – 1000 hours to white corrosion, 1500 hours to red corrosion (neutral salt spray)

Ductility

Temperature resistance

Abrasion resistance – harder than normal zinc plating systems

Applications

Automotive - fluid transfer tubes which can be deformed into their required shape after plating

Automotive – fasteners, particularly in areas of high corrosion (under hood, chassis joints)

Electronic – connectors, as a direct replacement for cadmium to provide corrosion resistance and high electrical conductivity.

Aerospace & defense - joining components in contact with aluminium

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.